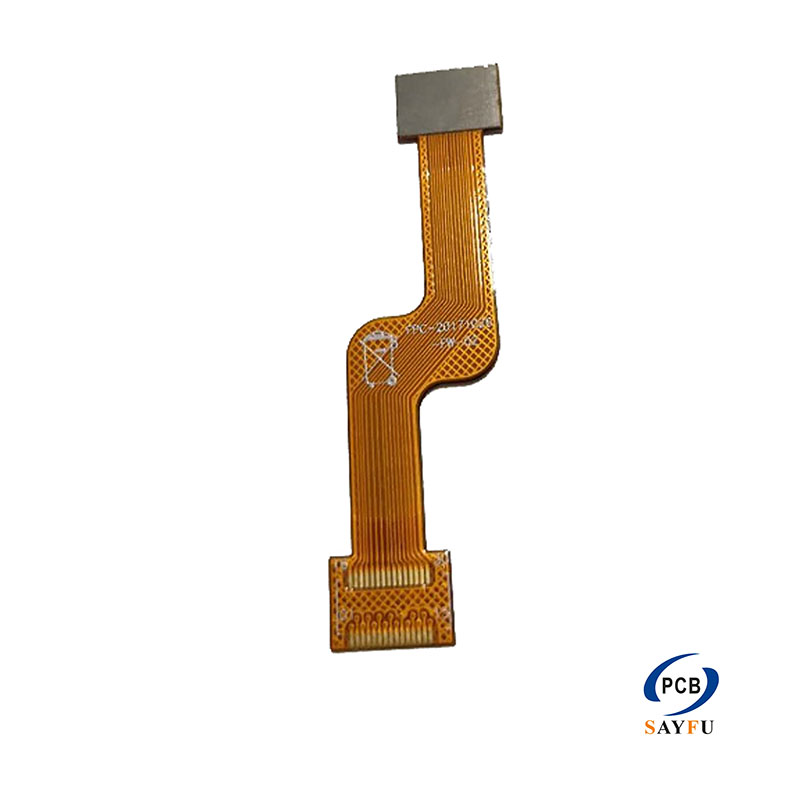

Flexible Printed Circuit board (FPC), also known as Flexible board, Flexible board or soft board, is divided into single-sided FPC, double-sided FPC, multi-sided FPC and rigid Flexible combination board. Flexible circuit board has the characteristics of thin, flexible, can meet the development trend of electronic products to miniaturization, thin, wearable, especially its characteristics of bending, winding and folding, can be arbitrarily moved and telescopic in three-dimensional space, convenient three-dimensional assembly of electronic products.

Due to FPC’s great advantages of being light, thin and flexible, the usage of FPC is also increasing. From communications, consumer electronics, automotive electronics, industrial control, medical, and military, aerospace, FPC is almost everywhere. Among them, automotive electronics is expected to replace mobile phones in the future and become an important driving force of FPC market, promoting the rapid growth of FPC market.

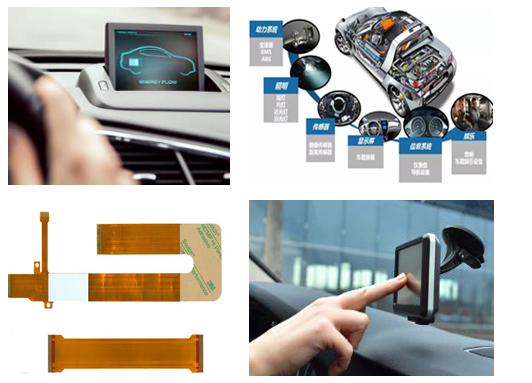

Automotive FPC main application fields

Automotive electronics is the general name of the vehicle body electronic control device and the vehicle-mounted electronic control device, mainly including engine control system, chassis control system and body electronic control system. As the main line of the future development of the automobile industry, new energy vehicles have become a trend to replace wiring harness with FPC, which will be used in many aspects of the car body.

With the increasing application of sensor technology and the gradual penetration of the Internet on the automobile, the trend of automobile electronization is becoming more and more obvious, and the proportion of automobile electronics in the vehicle cost is also rising. In 2010, automotive electronics accounted for 29.6% of the total vehicle cost, 34.3% in 2020. By 2030, the total vehicle cost accounted for nearly 50%.

At present, automotive electronics used in new energy vehicles account for more than 50% of the vehicle cost, and FPC will also be significantly improved in the consumption ratio of the vehicle. It is expected that the consumption of FPC per vehicle will exceed more than 100 pieces. More importantly, the PCB usage of new energy vehicles will be 5-8 times that of traditional vehicles, and the automobile PCB market will increase the penetration rate of new energy vehicles and get a rapid growth.

Global FPC market size for automobiles

According to the statistics of Zhanxin PCB Industry Research Institute, the market size of automobile flexible circuit board (FPC) reached 5.3 billion yuan in 2018, with a year-on-year growth of 8.4%. The main growth power of the market comes from the improvement of automotive electronization and the improvement of the penetration rate of new energy vehicles. The global market is expected to reach 5.7 billion yuan in 2019, up 7.0% year on year. From 2016 to 2022, the annual growth rate of FPC for automobile will remain between 6%-9% for a long time, and the market size of FPC for automobile will increase to 7 billion yuan by 2022. In 2018, the global sales of electric vehicles surpassed the 2 million mark, reaching 2.18 million units, up 65% from 2017, and accounting for 2.1% of total global vehicle sales.

According to the data of China Association of Automobile Manufacturers, in 2018, the production and sales volume of new energy vehicles in China reached 1.27 million and 1.256 million respectively, up 59.9% and 61.7% respectively. Among them, 986,000 and 984,000 pure electric vehicles were produced and sold respectively, up 47.9% and 50.8% over the same period last year. The production and sales of plug-in hybrid electric vehicles reached 283,000 units and 271,000 units respectively, up 122% and 118% over the same period last year.